All classifications

Bulk material scale

Bulk material scale

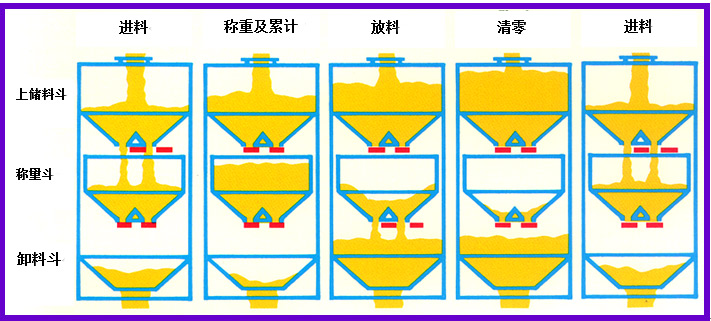

The bulk material scale can divide a batch of bulk material into several discrete loads, weigh each weight in turn, and then accumulate these load value values to obtain the total material value. Because it replaces dynamic metering with static metering, it is not affected by factors such as equipment vibration and material uniformity during the conveying process, which greatly improves the measurement accuracy, and can meet the receiving, transshipment, distribution and quantitative loading of bulk materials. A variety of weighing function requirements. It is mainly composed of weighing hopper, bracket, pneumatic valve, high-precision load cell, junction box, signal cable and intelligent weighing display. The weight of the material acts on the sensor and is converted into an electrical signal, which is amplified by the amplifier in the measurement circuit for display, recording and data processing. The bulk material scale can be called gross weight, tare weight and net weight, and has automatic zero adjustment and weighing data processing functions.

It is suitable for receiving/delivery/intermediate measurement of bulk materials in grain storage, grain processing, beer brewing, feed processing, grease and other industries. It can communicate with the upper control system in real time and can print in real time. It can also be used for fixed value loading and automatic batch weighing system.

Features

Measurement accuracy Static III; Dynamic: 0.2

Continuous conveying, static metering, with cumulative quantitative or batch quantitative mode

Fully enclosed weighing structure, fast, stable and reliable

Strict surface treatment for a variety of environments

Special material grinding layer to improve the service life of equipment

Pressure balance system further improves weighing accuracy

Fault alarm and monitoring of working status

Complete material data management and report printing

Computer interface output

Reasonable structural design ensures the stability of equipment operation and facilitates equipment maintenance.

Good human-machine interface and communication system facilitate manual operation and data management.

The bulk material scale can divide a batch of bulk material into several discrete loads, weigh each weight in turn, and then accumulate these load value values to obtain the total material value. Because it replaces dynamic metering with static metering, it is not affected by factors such as equipment vibration and material uniformity during the conveying process, which greatly improves the measurement accuracy, and can meet the receiving, transshipment, distribution and quantitative loading of bulk materials. A variety of weighing function requirements. It is mainly composed of weighing hopper, bracket, pneumatic valve, high-precision load cell, junction box, signal cable and intelligent weighing display. The weight of the material acts on the sensor and is converted into an electrical signal, which is amplified by the amplifier in the measurement circuit for display, recording and data processing. The bulk material scale can be called gross weight, tare weight and net weight, and has automatic zero adjustment and weighing data processing functions.

It is suitable for receiving/delivery/intermediate measurement of bulk materials in grain storage, grain processing, beer brewing, feed processing, grease and other industries. It can communicate with the upper control system in real time and can print in real time. It can also be used for fixed value loading and automatic batch weighing system.

Features

Measurement accuracy Static III; Dynamic: 0.2

Continuous conveying, static metering, with cumulative quantitative or batch quantitative mode

Fully enclosed weighing structure, fast, stable and reliable

Strict surface treatment for a variety of environments

Special material grinding layer to improve the service life of equipment

Pressure balance system further improves weighing accuracy

Fault alarm and monitoring of working status

Complete material data management and report printing

Computer interface output

Reasonable structural design ensures the stability of equipment operation and facilitates equipment maintenance.

Good human-machine interface and communication system facilitate manual operation and data management.

We can provide different material scale structure according to customer's needs to meet the needs of different occasions.

Previous:Loading system

Next:No